Ductwork Service & New Installation in South Florida

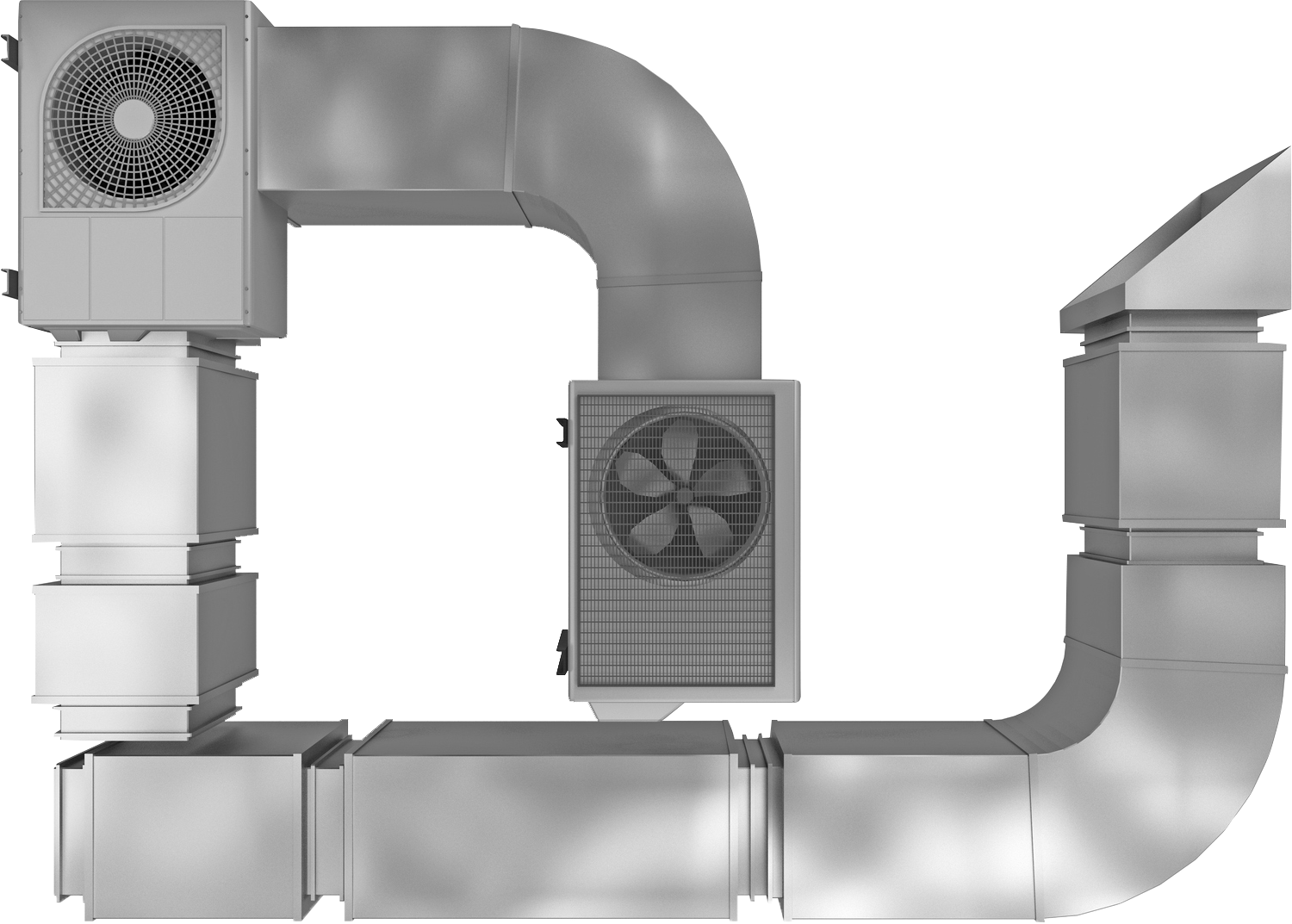

At Soo Kool Air Conditioning in Deerfield Beach, FL, we feel that ductwork is essential to your residential and commercial HVAC system. It functions as a passageway network that enables heated or cooled air to circulate throughout your space. Knowledge of ductwork and its purpose is crucial for anyone involved in HVAC system design and maintenance or even homeowners who want to understand their home's climate control system better.

The Importance of Ductwork in HVAC Systems

Properly designed ductwork is essential for maintaining consistent temperatures in all rooms, contributing to the overall comfort and well-being of the building's occupants.

Ductwork also plays a vital role in maintaining indoor air quality. The movement of air through ducts facilitates the removal of particles and contaminants, ensuring that the air circulating throughout the building is clean and healthy. This is especially important for individuals with respiratory issues or allergies.

Another key benefit of efficient ductwork design is energy efficiency. Effective ductwork minimizes energy loss, ensuring the HVAC system operates as effectively. This is crucial for environmental and economic reasons, as it helps to reduce energy consumption and lower utility bills.

Our Ductwork Installation Service Explained

Ductwork comes in various types, including rectangular, round, and spiral. Rectangular ducts are the most common and are often made of galvanized steel, aluminum, or fiberglass. Round ducts, on the other hand, are typically made of aluminum or fiberglass. Spiral ducts are made of galvanized steel and are ideal for large commercial buildings due to their durability and strength.

Ductwork can also be insulated or uninsulated, depending on the building's specific needs. We will discuss the exact type of duct system that will perfectly match your needs and budget.

Indoor Air Quality

Poor indoor air quality can negatively impact your health and comfort, causing allergies, respiratory problems, and other health issues. Our team of experts can help improve indoor air quality through services such as air duct cleaning, air purifiers, and proper ventilation. We strive to provide our customers with a comfortable and healthy living environment.

Air Ventilation UV Ultra-Light

Air Ventilation UV Ultra-Light offers several benefits for your home or business. It helps to improve indoor air quality by removing harmful pollutants such as bacteria, viruses, and allergens. This technology uses ultraviolet light to sterilize the air as it passes through the HVAC system, killing these harmful pollutants and improving the overall air quality. It also helps to reduce unpleasant odors and can improve the efficiency of your HVAC system. With Air Ventilation UV Ultra-Light, you can breathe easier knowing that your indoor air is clean and healthy.

Attention to ductwork is crucial for optimal system performance, whether for a new installation or upgrading an existing system. Call

954-825-7182 to learn more.